Shipping containers are the unsung heroes of global trade, silently ferrying goods across oceans and continents. ASTM D999 – Vibration testing of shipping containers the ultimate guide to vibration testing for shipping containers.

Purpose and significance of vibration testing for shipping containers

Shipping containers play a crucial role in the transportation of goods across vast distances. They endure various environmental conditions and handling procedures, which can potentially cause damage to the contents inside. This is where vibration testing comes into play.

The purpose of vibration testing for shipping containers is to simulate the vibrations experienced during transport and identify any potential weaknesses or vulnerabilities in their design. By subjecting containers to controlled vibrations, we can assess how well they withstand these dynamic forces.

Significantly, this type of testing helps ensure that the products being transported remain intact and undamaged throughout their journey. It allows manufacturers and suppliers to identify areas for improvement in container design or packaging methods, reducing the risk of costly delays, product loss or customer dissatisfaction.

Types of vibration tests covered by ASTM D999

The ASTM D999 – Vibration testing of shipping containers this standard covers various types of vibration tests that are specifically designed to assess the durability and reliability of shipping containers.

These tests simulate the vibrations that containers may encounter during transportation, helping manufacturers and shippers evaluate their resistance to potential damage.

One type of test covered by ASTM D999 is the random vibration test. This test involves subjecting the container to random vibrations with a wide range of frequencies and amplitudes. It aims to replicate real-world conditions where containers may experience different types of vibrations simultaneously.

Another important test is the sinusoidal vibration test, which focuses on specific frequencies and amplitudes. By subjecting the container to these controlled vibrations, manufacturers can determine its response at different resonant points.

The third type of vibration test included in ASTM D999 is the fixed-frequency resonance search method (FFRSM) test. This method helps identify critical resonance points in a container’s structure that may lead to excessive stress or damage during transportation.

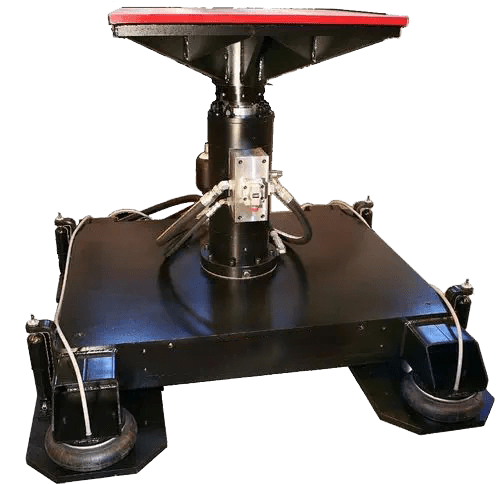

Furthermore, there are vertical vibration tests, horizontal vibration tests, as well as rotary motion testing methods specified within this standard. Each type has unique characteristics and objectives for evaluating different aspects of container performance under dynamic conditions.

Benefits of using ASTM D999 for shipping container testing

When it comes to shipping goods, ensuring the safety and integrity of the containers is paramount. That’s where ASTM D999 comes into play. This standard provides guidelines for vibration testing of shipping containers, helping to identify any potential weaknesses or vulnerabilities.

One of the key benefits of using ASTM D999 is that it allows manufacturers and shippers to assess how their containers will perform under real-world conditions. By subjecting them to various types of vibrations, such as random or sinusoidal motions, this testing can simulate the stresses they may encounter during transportation.

By conducting these tests, companies can gain valuable insights into the durability and structural integrity of their shipping containers. They can determine if any modifications are needed to improve performance and minimize damage during transit.

Another advantage is that ASTM D999 provides a standardized approach to vibration testing. This means that results obtained from different laboratories will be consistent and comparable. It ensures that everyone in the industry speaks the same language when assessing container performance.

Using ASTM D999 also helps companies meet regulatory requirements by demonstrating compliance with industry standards for packaging and transportation. It acts as a quality assurance measure, providing confidence in the reliability of shipping container designs.

Conclusion

ASTM D999 provides standardized guidelines for conducting vibration testing on shipping containers. By subjecting these containers to various types of vibrations that they may encounter throughout the journey, this test helps identify potential weaknesses or vulnerabilities that could lead to damage.

We cannot overstate the significance of vibration testing. It allows manufacturers and shippers to assess how well their packaging designs withstand real-world conditions and make necessary improvements if required. This not only ensures product integrity but also reduces costs associated with damaged goods.

By adhering to ASTM D999 protocols for vibration testing, companies demonstrate their commitment to ensuring customer satisfaction through safe delivery of goods while minimizing losses due to damaged shipments. Furthermore, compliance with international standards enhances credibility and trust among customers and business partners alike.

ASTMD 99 offers a vital framework for evaluating how well shipping containers endure vibrational stresses encountered during transportations – ultimately contributing towards safer deliveries and reducing costs associated with damaged goods.